Add to Cart

|

Automatic fiber cement board machine introduction |

FIBER CEMENT BOARD

Fiber Cement Board is a new construction material which has been pulping, molding, compression, maintenance and so on. It is based on cement and assist with proper fiber reinforced material. The products are widely used in variety kinds of industrial and domestic construction fields such as external, internal walls, ceilings, sound insulation, and waterproof board for special facility. Combined with keel and filler, it also can used for some framework light board system construction, high-rise building, old building renew, light type work shop, control room and laboratory. Because of its good features like less building cycle, less energy, notable economic benefit, fiber reinforced cement board are favorable all over the world.

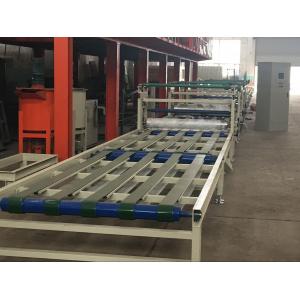

Fiber Cement Board Sandwich Panel Production Line/Mineral Fiber Cement Ceiling Board Making Machine

Fiber cement board production line:

| Item | Unit | Standard Fiber Cement Board |

| Density | g/cm 3 | <1.3 |

| Anti-bend strength | MPa | >9 |

| Heat conduction modulus | w/m.k | <0.29 |

| Anti-impact strength | kJ/mm 2 | >2.0 |

| Pull force of screw | N/mm | >75 |

| Dry shrinkage rate | % | <0.2 |

| Non-burn performance | In accordance with standard GB8624 First Class Non-burn Material |

| Advantages | ||

| Number | Item | Content |

| 1 | Low cost | Low labour and material costs |

| 2 | Long life | Up to 30 years |

| 3 | Recycling use | Reused for more than 10 times |

| 4 | Flexible layout | Layout adjusted according to your requirement |

| 5 | Environment protection | Environment-friendly materials used |

| 6 | Safe & Stable steel structure | Earthquake proof & Wind resistance |